Precision shaft alignment e-learning course

Precision-aligned machines run more smoothly and suffer fewer failures - plus they consume less energy. Precision alignment must be part of your reliability improvement strategy. Precision Shaft Alignment makes it easier to gain knowledge, confidence, and competence.

Precision alignment = reliability.

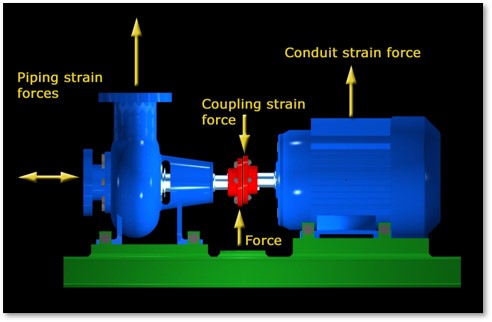

Achieving precision alignment (and eliminating soft foot) is one of the keys to achieving reliable rotating machinery. With each rotation of the shaft, misalignment puts the shaft, coupling, bearings, seals, and the support structure under undue stress and strain. It sucks the life out of the machine and consumes additional energy.

It is simply not adequate to use a straightedge or dial indicators (unless trained in the precision use of the dial indicators). Precision alignment and the elimination of soft foot (base and foot flatness, pipe strain elimination, etc.) are some of the fundamental skills of an organization seeking to improve reliability.

Easy to use ≠ easy to do

Unfortunately, it is common around the world for organizations to purchase laser alignment systems without providing the necessary training on how to use the system, or what it means to achieve precision alignment. As a result, maintenance technicians simply follow on-screen prompts and “go through the motions” to align the shafts. It is, therefore, common for machines to be operated with misaligned shafts and strained casings (due to soft foot).

It is critical that the maintenance technicians appreciate the importance of precision alignment and they understand what the measurements are telling them. They must also understand how to overcome the challenges that present themselves due to different machine designs and mounting issues.

It is simply not enough to purchase a laser alignment system and assume that you, therefore, have precision alignment.

E-learning: interactive, highly visual – learn again and again

The most common way our customers master precision alignment is via the this e-learning course. It can be purchased as a standalone product but it is included within the iLearnReliability™ Learning Management System

Precision Shaft Alignment provides step-by-step training, one slide at a time. The narrations add up to four hours and 39 minutes (968 slides), but it will take longer to complete the training. Quizzes on each topic area are also included in the training.

Although modern laser alignment systems are also quite visual, in many cases that means that the person performing the alignment doesn’t have a complete appreciation of what is happening as they make the various adjustments. This training will ensure that precision alignment can be achieved every time regardless of the situation.

Course topics

Precision Shaft Alignment provides step-by-step training, one slide at a time. The narrations add up to four hours and 39 minutes, but it will take longer to complete the training. Quizzes on each topic area are also included in the training.

- An overview of precision alignment

- A detailed introduction to alignment including the reliability benefits

- The basics of dial-indicator calculations

- Rim-and-face and reverse-dial dial-indicator alignment overview

- Pre-alignment checks

- Soft foot detection and correction

- The rim-and-face method in detail

- The reverse-dial method in detail

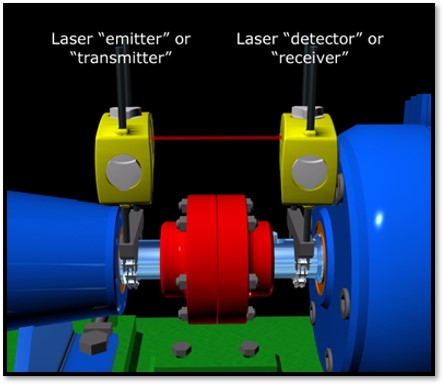

- Laser alignment methods in detail

- Moving the machine (and how to deal with the bolt bound and base bound situations)

- Dealing with dynamic and thermal growth

- Machine train alignment

While you can skip the dial indicator training, most experienced alignment practitioners have found that understanding dial indicator alignment has helped them achieve much better results with laser alignment. They find it helps them understand exactly what the laser alignment systems are doing.